-

Bottle Jack

-

Floor Jack

-

Mechanical jack

-

Scissor Jack

-

Air Jack

-

Farm Jack

-

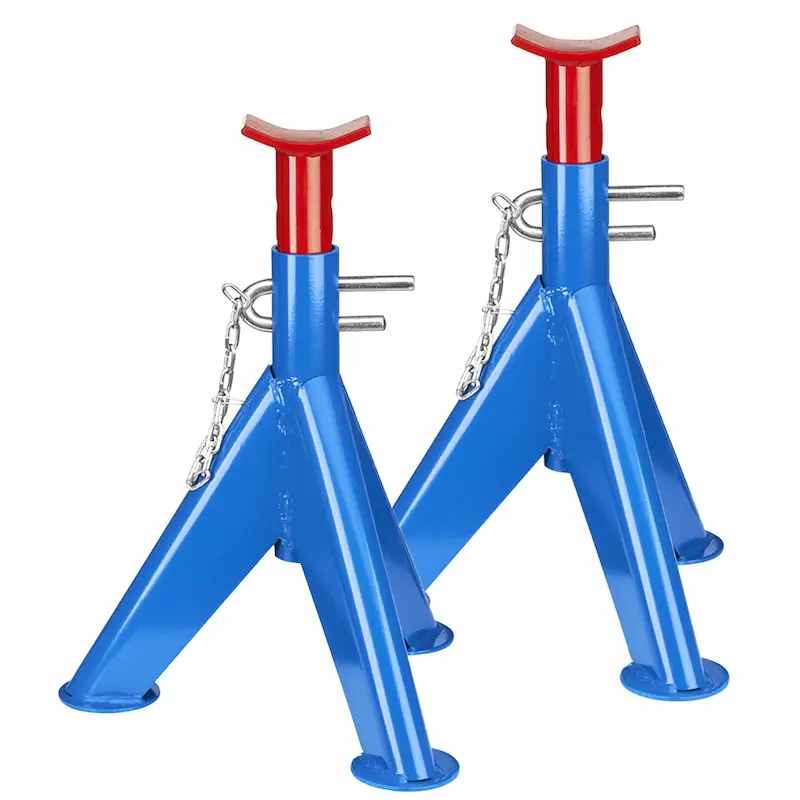

Jack Stands

-

Heavy-duty Jack Stands

-

Heavy-Duty Vehicle Support Stands

-

Vehicle Dolly

-

Wheel Chocks

-

Creeper and Seat

-

Car Lift Service Ramp

-

Shop Press

-

Transmission Jack

-

Engine Stand

-

Engine Crane

-

Accessories for Engine Crane

-

Spring Compressor

Hydraulic Jacks & Workshop Equipment

More

Automotive Lifts & Parking Solutions

More

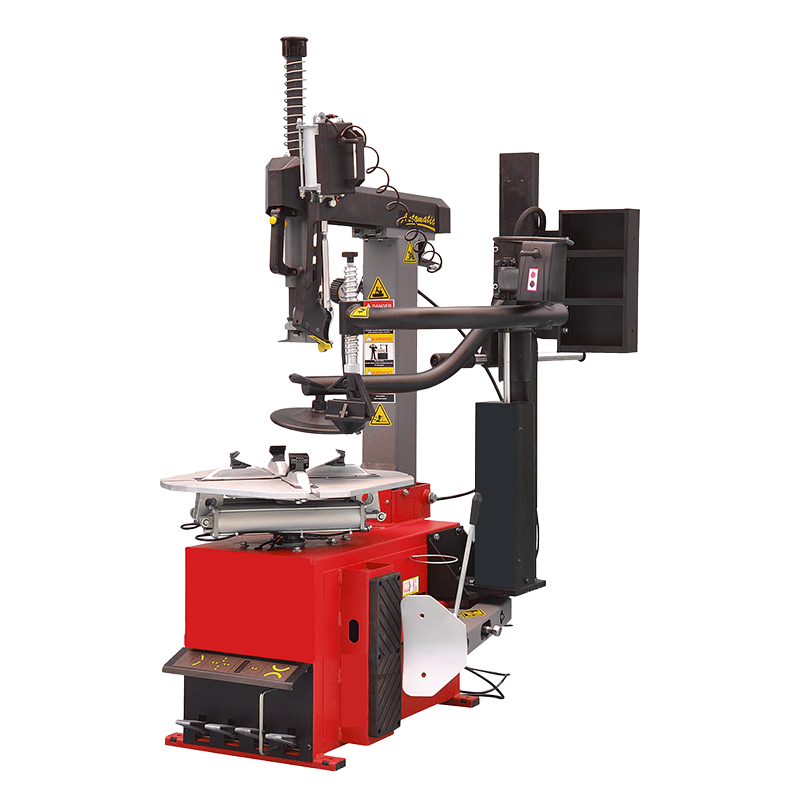

Tyre Service Equipment

More

Diagnostic Tester & Battery Tools

More

Fluid & Lubrication Equipment

More

Maintenance Equipment

More

Auto Body Shop Equipment & Tools

More

Cleaning & Detailing Equipment

More